Standard-Gum transforms a wide range of materials.

Thermoplastics. With amorphous or crystalline structure, thermoplastics have the characteristic of becoming plastic with heat. This means they can be formed at high pressure with a press in the mould. Once cooled, the plastic part takes on its final characteristics. There are very many families of thermoplastics, with varied properties: flexible, rigid, high modules, translucent, transparent, etc., everything is possible! Contact us!

Thermoplastics come in the form of beads which are melted and injected at very high pressure.

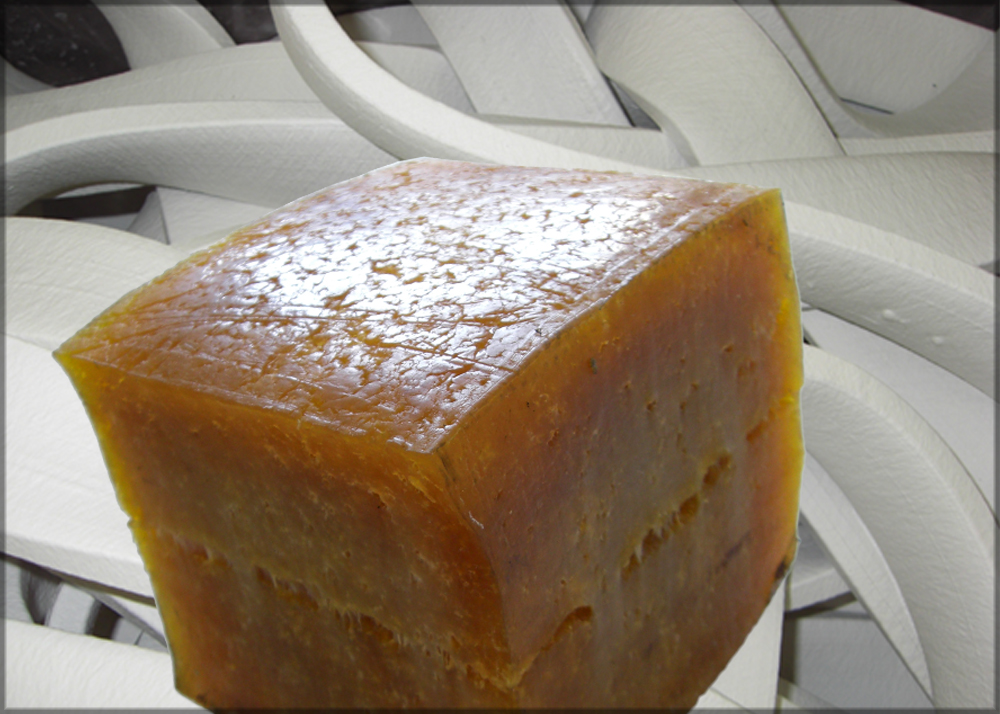

Vulcanised materials, rubber.

It is either synthetic or natural. Additives are mixed with an elastomer base to adapt the properties to the final product. It is injected at high pressure as a paste into a mould which gives it its shape. Unlike thermoplastics, it is cured and cross-linked irreversibly. Rubber is essential with its qualities of strength, longevity and elongation.

Silicon. Made from silicon, it is injected as a paste mixture and is vulcanised like rubber. Silicon parts are remarkable for their chemical inertness and temperature resistance.

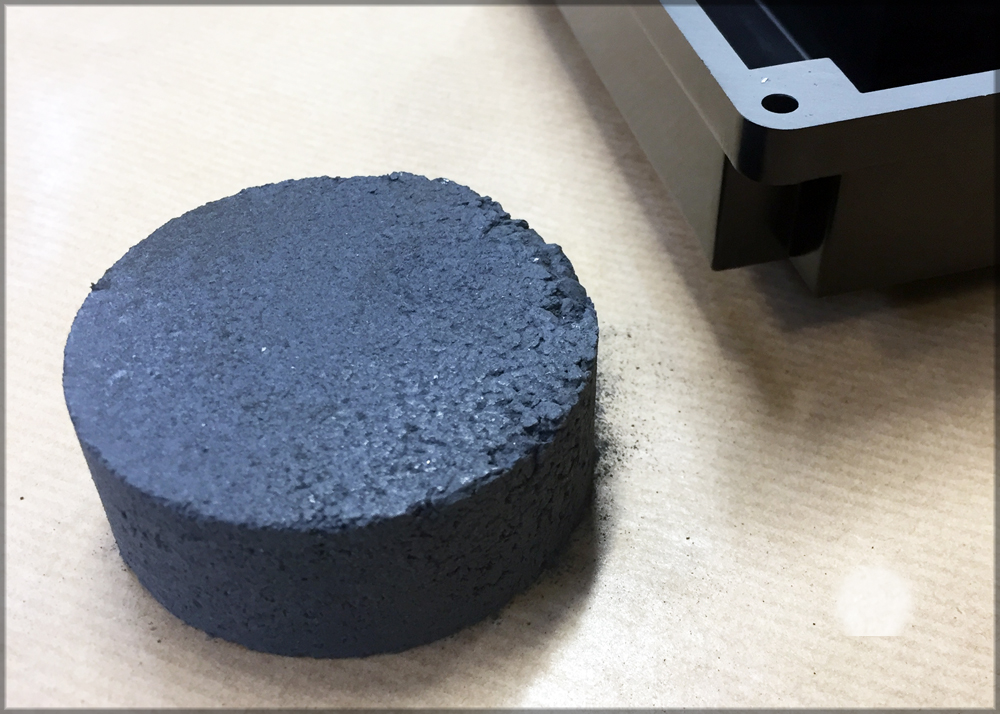

Thermosetting materials

Thermosetting materials are resins irreversibly cross-linked with heat. Thermoset parts have excellent electrical properties. They are very resistant to temperature, chemical aggression and are dimensionally stable. An ally in the most limiting environments!